jaw crusher eccentric shaft design

Gyratory Crusher - an overview | ScienceDirect Topics

Figure 8.1 shows two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action of the moving jaw. A double toggle crusher has, basically, two shafts and two toggle plates.

PDF Jaw Crushers - TerraSource GlobalPDF

Jaw Crushers - When Only the Most Massive, Rugged and Cost-Effective Jaw Crusher in the Industry Will Do! The massive cast steel pitman and forged alloy steel eccentric shaft are supported by four anti-friction roller bearings. Applications Employed as a primary crusher, the overhead eccentric jaw crusher is used in quarries, cement plants,

Jaw Crushers - Prime Machine, Inc

Machining babbitt bearing for Jaw crusher. Eccentric shaft jaw crusher being welded. Eccentric shaft Jaw Crusher prep for sub arc weld shaft. jaw crusher toggle

Manufacturing and refurbishing of jaw crushers - RocketCDN

each rotation of the eccentric shaft the swing jaw opens and In 1881 Philetus W. Gates patented a design for a crusher, the.

design of eccentric shaft for jaw crusher

eccentric shaft design of jaw crusher – Grinding Mill China. The Design of Rolling Bearing Mountings: Design ,Speed of eccentric shaft n = 1,800 min–1; radial load Eccentric shaft to k5, housing bore to M6.

VIBRATING ECCENTRIC SHAFT | Crusher Mills, Cone Crusher, Jaw Crushers

Your Overall Features: Dual Shaft Eccentric Gear Drive Convey the Materials from Jaw Crusher to Vibrating Screen, Simple pendulum how does a jaw crusher work works , mating of 2 eccentric shaft timing for vibrating feeder,

Computer Aided Design of Jaw crusher” - ethesis

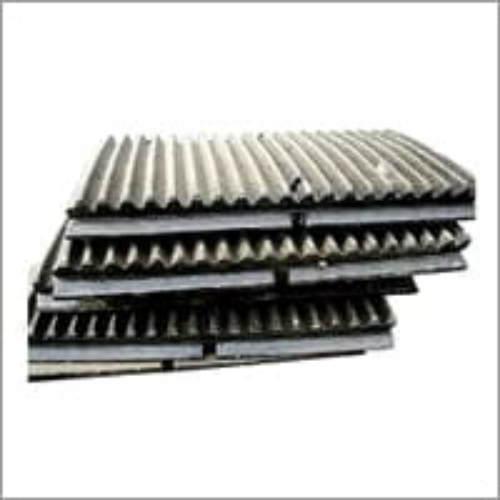

Eccentric Shaft is machined out of Alloy Steel Fitted with anti-friction bearings and is housed in pitman and dust proof housing. Rotational energy is fed into

MEKA Jaw Crushers - Berkshire Engineering Supplies

MEKA Jaw Crushers are designed for cost-efficient primary reduction of A very large eccentric shaft and four large spherical roller bearings ensure the

eccentric shaft design in jaw crusher

The Eccentric Shaft of Jaw Crusher Jul 29 2014. The eccentric shaft of jaw crusher is used to transmit torque and make the equipment rotating in jaw crusher. So it should not only bear bending load but also transfer torque in operating. There is a strictly requirement to the material and design of the eccentric shaft. I will answer this

Eccentric Shaft Crusher Video | Crusher Mills, Cone Crusher, Jaw Crushers

The main rack structure of Jaw Crusher are the eccentric shaft, the pulley, flywheel, moving jaw , side rack , elbow plate, , Crusher - Wikipedia, the free encyclopedia, The short-shaft design has superseded the long-shaft design in which the eccentric is mounted below the gear. Cone Crusher. Cone crusher.

Knowing the Basics Leads to Better Care - Timken Company

In a typical jaw crusher, two outer bearings located on either side of the , main frame support an eccentric shaft, while two inner bearings support , a movable jaw. These are commonly known as "Pitman" bearings. The , reciprocating motion of the shaft moves the Pitman against a second, , stationary jaw.

+86-21-63353309

+86-21-63353309

Leave a Comment