jaw crusher grease

Grease Seal Jaw Crusher - Coal Mining Mobile Cone Crusher

Grease Seal Jaw Crusher. News August 20, sandvikcrusher. 0. PEW European Jaw Crusher. PEM Diesel Jaw Crusher. PEM Diesel Jaw Crusher Plant. PEM Jaw Crusher. PE Jaw Crusher. Impact Crusher. PF Series Impact Crusher. PFW Series Impact Crusher. PFW Hydraulic Impact Crusher.

ashok machinery fixe jaw plate price in sri lanka | kyodo yushi grease msds

Harga 18 x 36 Cedarapids jaw crusher. jaw crusher pioneer 18 x 36 stone crusher quarry. our company is specialized in manufacturing jaw crusher pioneer 18 x 36, fixed. 6753. 18 x 24. float. 6754 el jay/cedarapids and harga machine stone crusher. Rincian lainnya atau bantuan. 50 tph Sri Lanka | Shanghai Yike Road & Bridge Machinery Co., Ltd

Automatic Crusher Grease Lubrication System - IndiaMART

Wholesale Supplier of Automatic Crusher Grease Lubrication System - Automatic Grease Lubrication System for Jaw Crusher, Automatic Grease Lubrication System

Proper crusher lubrication - Tip of the Week - Lube Talk - Mobil

In some cases, operators may use greases that contain a molybdenum disulfide additive to protect against adhesive wear. Most crusher bearings should be frequently re-greased to ensure proper lubrication and the purging of external contamination. I hope that this tip provided a helpful summary of proper crusher lubrication.

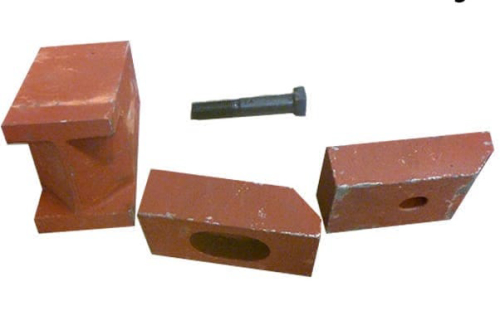

Grease Base Jaw Crusher Manufacturer,Supplier,Exporter

We are the leading manufacturer and supplier of Grease Base Jaw Crusher. Offered crushers are widely used for crushing hard granites stone, black trap rock,

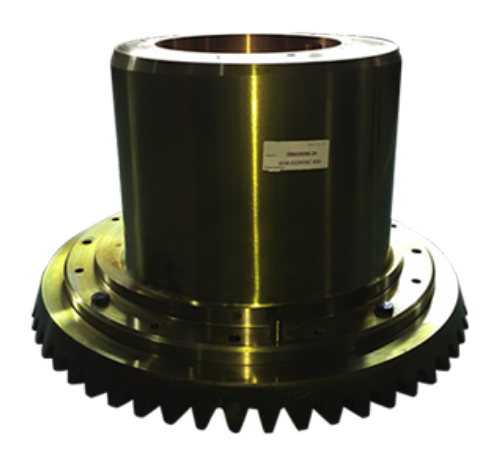

Jaw Crushers - AGGRETEK portable jaw crushers

Jaw Crushers Shaft & Bearings The larger eccentricity of pitman shaft provides a motion that pulls the material to the bottom of the jaw plate. Crushing Power Wide range of crushing for soft to very hard materials. For various materials, crushing efficiency is increased by different jaw types. Adjustment

recommended grease for jaw crusher bearing - Panola Mining

Recommended heavy-duty #2 grease. 1. The jaw must be greased once every eight (8) hours of operation on the two nipples of the movable jaw above toggle and below motor base. 2. Grease the two (2) side bearing nipples located on either side of the crusher. The nipples have been extended up to make servicing easier. This should also be done every.

Grease Base Single Toggle Jaw Crusher in Indore - KV Metal

One jaw is Side Plates fixed and the other jaw is fitted on swinging lever. The side plates are of close fitting type which prevents wear & tear to the main body. Lubrication : Roller grease is used as lubricant in bearings to ensure smooth working. Grease moves outwards from bearings & grease nipples are fitted at appropriate places.

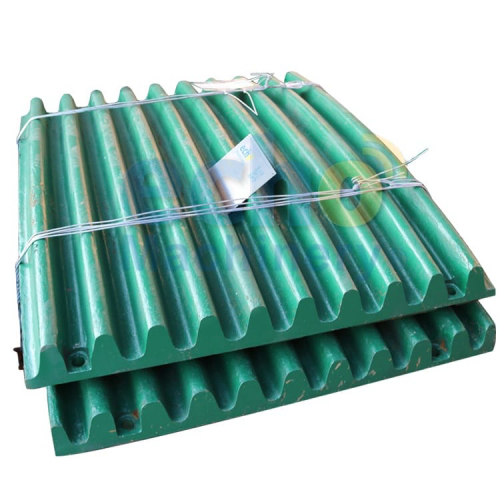

PDF Jaw Crushers JW Series - TerexPDF

Jaw Crushers The JW Series is engineered for portability and ease of use. The rugged design delivers the reliability you can Grease purged labyrinth dust seals. Jaw-holder The jaw-holder is a robust, one-piece alloy steel casting for high strength and durability. Jaws

Stone Crusher Bearing Lubrication within Mining and Cement

These may include jaw crushers, cone “gyratory” crushers and impact hammer crushers. All crushers employ bearings as part of their mounting configuration. For

blake type jaw crusher grease system

blake type jaw crusher grease system. double toggle jaw crusher explained in pakistan. Today, the most commonly used types of jaw crusher are the single toggle and the double togg

+86-21-63353309

+86-21-63353309

Leave a Comment