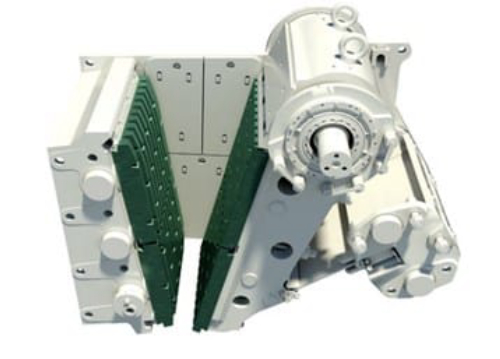

jaw crusher liners

Liner wear in jaw crushers

They only register compressive/tensile forces. The liner material is manganese alloy steel, commonly used for crusher liners, with 1.2% C, 12.5% Mn, 0.6% Si and

Jaw Plate Manufacturer | Bowl Liner | Blow Bar - Casteel Foundry

Jaw Liner is important to having quality finsihing and pefect fitting with jaw stock and frame,espeically the machining area of the back side are required pefect fitting with assembly to have less vibration, 2021-12-24. Primary Crusher: Minyu 4032 Jaw Secondary Crusher: Minyu MSP200 Hydraulic Cone crusher Titary Crusher: Minyu MCC40

PDF C series jaw crushers Wear parts application guidePDF

In the C jaw crusher, the feed opening is measured from the top of the tooth of the fixed jaw to the bottom of the tooth of the movable jaw in a straight line perpendicular to the center line of the crushing cavity. The maximum feed size is approximately 80% of the feed opening. Feed opening depth Cavity width mm in mm in,

Manganese Jaw Liners - Crusher Spares

Crusher Spares (Australia) stock and supply an extensive range of aftermarket manganese jaw crusher liners to suit the majority of the different

Crusher Wear Parts | Weir ESCO

Jaw Crusher Wear Parts, Jaws, Ready-to-order or custom-engineered. Select from Maximum Productivity, Longer Life, or Special Application variants. Fabricated Cheek Plates, Ready-to-order, Gyratory Crusher Wear Parts, Mantles, Ready-to-order or custom-engineered, Custom-engineered, Rim liners and spider arm liners, Ball caps and spider caps,

Jaw Crusher Plates | Chrome White Iron

Our jaw crusher plates, cast and machined chrome white iron protection covers and wear plates, chrome carbide overlaid plates/curves, and other parts are

Liner wear in jaw crushers - ScienceDirect

01/01/2003 · The small jaw crusher was used to study the wear as a function of force (i.e. pressure) and motion. The experiments were carried out using quartzite, since this material is known for being very abrasive. The size distribution of the feed material was 8–11 mm.

Manganese Parts - Australian Crushing and Mining

Australin Crushing & Mining Supplies are able to offer aftermarket Blow Bars & liner plates, we also have developed a range of impact bars to suit the

ESCO ® Crusher Wear Parts

wear parts for all major makes and models of cone, jaw and gyratory crushers. Mantles and liners: ready-to-order or Custom-Engineered Accessories

Jaw Crusher Liners - Makuri Group

Jaw Crusher Liners High availability and good product shape are crucial for overall plant efficiency. A lack of attention to proper jaw design by OEMs results in poor product shape and

Jaw Crusher Liners - Tempus Steel

Jaw Crusher Liners Selecting the right jaw profile can not only significantly improve jaw crusher performance but also secondary crushing efficiency by

+86-21-63353309

+86-21-63353309

Leave a Comment