jaw crusher repair

Jaw Crushar Bearing Chenge

Apr 04, · Jaw Crushar Bearing ChengeJaw Crusher Bearing Chenge Keshe kareJaw Crusher Bearing Chenge asan tarikaJaw bearing Chengewelcome to my ChannelJaw Crusher Beari

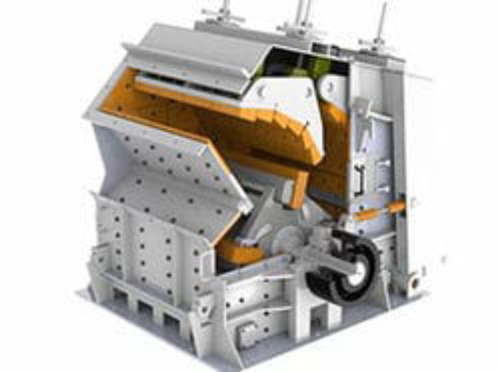

Repair 10 parts of Jaw crusher that are prone to failure

Jul 16, · FODAMON engineers will analyze the repair methods for the top 10 parts of jaw crusher that are prone to failure, and teach you to repair the jaw crusher hand in hand. #01 Foundation treatment

Jaw crusher frame crack repair measures

The jaw crusher is one of the main mine crushing machinery. Due to the poor working environment, the frame of the jaw crusher may crack. Great Wall Casting (CHAENG) believes that this situation can not be ignored and should be solved and repaired as soon as possible. Many enterprises often ignore these problems, resulting in greater problems.

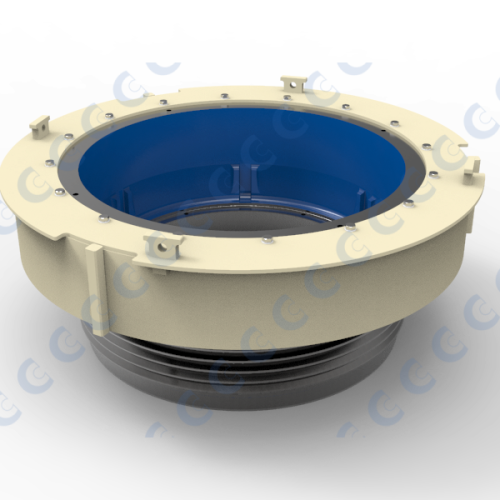

SPRING CONE CRUSHER REPAIR | Crusher Mills, Cone Crusher, Jaw Crushers

Search cs cone crusher repair manual to find your need. cone crusher、Hydraulic cone crusher、China cone crusher、spring cone crusher, CS series high cone crusher disasembly spring cone crusher structure,parts,repair,work principle. spring cone crusher usually takes as primary crusher machine in mining industry, quarry plants,

jaw crusher repair | C100 LINER

May 28, · Sanme Machinery (JV with Hazemag Germany) provides you: crusher, cone crusher, mobile crusher, impact crusher, jaw crusher, sand maker and the Sand production line. Tel:+86-371-64966668." Stone jaw crusher working principle in 2021. A jaw crusher consists essentially of two crushing plates, inclined to each

How to Repair the Jaw Plate of Jaw Crusher?

The main repair method of jaw crusher is surfacing. · Polish 2-3mm on the surface which need to be welded before welding. · Main part should avoid

PDF ® C Series™ jaw partsPDF

across the crushing chamber. 3. Apply proper scalping • Fines (material smaller then CSS) should be removed from the feed material. This is done by the grizzly bar section of the feeder. Fines in the jaw crusher increase the percentage of contact area against the jaw dies. This increases scratching and grinding and reduces life time. 4.

The Most Practical Jaw Crusher Repair and Maintenance Manual

How to replace jaw crusher plates? Inspection and maintenance of other parts Check whether the discharge port is blocked, remove the blockage in time, and keep the discharge unobstructed. Check whether the V-belt is loose. If it is too loose, you need tight it because loose belt will cause slippage. Whether the eccentric shaft is blocked.

extec c12 jaw crusher repair manual

extec c12 jaw crusher repair manual. extec c crusher manual free download. extec c12 jaw crusher repair manual giovannigabbiano.eu.As a leading global manufacturer of crushing and

jaw crusher repair | most popular crusher spare wear copper casting for

The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws .For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square. Large, Medium and Small Repair of Stone Jaw Crusher. Mar 05, · 1, minor repair. The minor repair needs to inspect and

what are the maintenance of primary jaw crusher

Maintenance and Repair of Jaw Crusher | JXSC Mine.

+86-21-63353309

+86-21-63353309

Leave a Comment