jaw crusher toggle plate work

OPTIMUM DESIGN AND ANALYSIS OF SINGLE TOGGLE

TOGGLE JAW CRUSHER. Shyam Sundar.V The job is helpful for a design of new prototype of this kind of the weight of the swing plate of jaw crushers.

PDF) Selected design issues of toggle plate selection on

A jaw crusher is a kind of size reduction machine which is widely used in mineral, aggregates and metallurgy fields. The performance of jaw

How does a Single Toggle Jaw Crusher work? | RUBBLE MASTER

An elliptical motion is created by an eccentric shaft passing through the top of the jawstock which pivots around a toggle plate at the lower half of the jawstock. This geometry turns the rotary motion of the eccentric shaft into a fore aft motion at the bottom of the jaw plate creating the crushing action.

Jaw crushers, Stationary Jaw crusher series — SRP

Each jaw crusher comes with feed hopper, feed hopper interface, drive and subframe with v-belt guard and motor bracket, our unique guarding retraction arrangement and toggle plate stop. The wide range of jaw plates can be mixed and reversed to ensure optimal, versatile crushing. EASY TO SET UP AND INSTALL,

PDF) Selected Design Issues of Toggle Plate ... - ResearchGate

For this purpose, information about kinematic analysis jaw movements was provided on the example of a single toggle jaw crusher. The analysis

jaw crusher toggle plate work | mill separator bearings

jaw crusher toggle plate work RTRYCDMP BRACKET SMB30MM, 27162. Aimix Machinery > Concrete Plant > Dry Mortar Production Line. Toggle Plate Jaw Crusher is mainly used to crush kinds of mining stones primarily, and the largest compression resistance of the material is 320MPa. The jaw crusher is widely used in stone mining, metallurgy industry

What is the jaw crusher adjustment device? - Quora

The motor transmits power through belt, drives the moving jaw do periodic motion to the fixed jaw surround the eccentric shaft. The angle between toggle plate

How does a Single Toggle Jaw Crusher work?

An elliptical motion is created by an eccentric shaft passing through the top of the jawstock which pivots around a toggle plate at the lower half of the jawstock. This geometry turns the rotary

jaw crusher toggle plate work cnc precision milled bronze parts

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

In- depth – Components of a Jaw Crusher | PROPEL INDUSTRIES

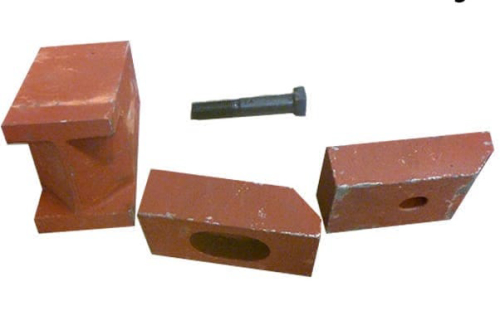

Here, it refers to the moving jaw in a jaw crusher. It achieves the reciprocating movement through the eccentric motion of the flywheel shaft. This creates enormous force in each stroke. The pitman is fitted with two replaceable high strength steel alloy toggle plate. 3. Jaw Plate,

Jaw Crusher – Single Toggle vs Double Toggle - JXSC Mine

The movable jaw and static jaw are made up of the crushing chamber. It stimulates the movement of the two jaws of the Animal and completes working. Widely used

+86-21-63353309

+86-21-63353309

Leave a Comment