planetary gearbox design

DESIGN AND CALCULATION OF PLANETARY

Abstract: In this paper, the design and calculation of planetary transmission with bevel gears for road vehicles is presented. It must transfer power to the

Gearbox Design Tool - Apex Dynamics USA

Gearbox Design Tool; Gearbox Design Tool. The Most Professional Servomotor Drive Planetary Gearbox Manufacturer in the World. Apex Dynamics, Inc. is a worldwide leader in manufacturing of planetary gearboxes. Based on more than twenty years of accumulated manufacturing and marketing experience, plus the highest level of technical production

planetarybox | [email protected]

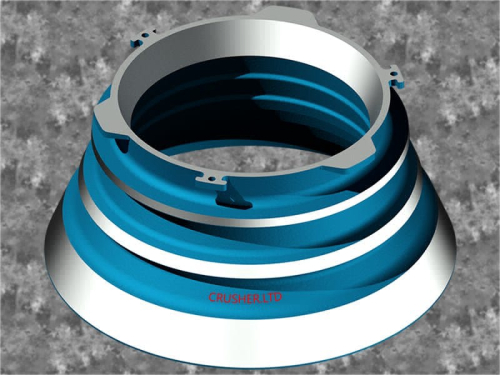

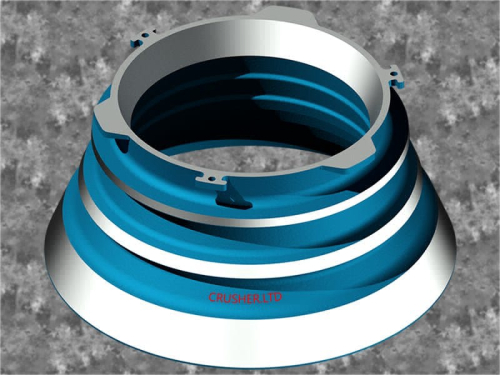

A planetary gearbox is composed of three main components: a sun gear, an input bevel gear, and an output shaft. A planetary gearbox can have different output torques and ratios. The basic model of a planetary gearbox is highly efficient and transmits 97% of the power input.

Material Selection for Optimum Design of Planetary Gear Train

The materials utilized for gears are nodular graphite cast iron. The material properties and costing of pinion and gear material were studied, and standard gear

Planetary Designs – Gear.com

Planetary Design was born in 2005 from a Montana man’s desire for a barista-quality brew in the backcountry. The first of its adventure-worthy coffee gear was a french press. Since then, Planetary Design has introduced a variety of other products to the outdoor world, including airless storage solutions for freshly roasted coffee beans, tea

Planetary Gearbox Design | Heason Technology | Heason

Planetary Gearboxes have a unique design and way of working. The input and output gears rotate around the pinion or “sun gear”. The centre of the input gear revolves around the centre of the output gear and the input and output shafts are aligned.

Home - servo planetary gearbox

Servo Planetary Gearbox is a versatile industrial product, its performance is comparable to that ofmilitary grade planetary reducer products, but with the price of industrial grade products. " Right-angle design allows motor to be positioned at 90 degrees to the reducer,

Designing Planetary Gearboxes in Fusion 360 for Robotics

Step 3: Lets Start Making Something! I'm going to design a planetary gear with 4 planet gears and I'm going to use the carriage as the output with screws going out of it as an attachment point. I decided I want a 4:1 gearbox so I used a 20 tooth module 1 gear for sun and planet gears and 60 tooth gear to cut the ring gear.

Design and Optimization of Planetary Gears ... - Gear

The following shows the gear optimization in some case studies: Load distribution. Next to the load distribution factor Hβ K one of the important tasks of gear development is to optimize Figure 3 Design process of a gear as a system. Figure 4 User interface of MDESIGN gearbox with 3-D-GearDesigner and result page (Ref. 10).

Planetary gearbox Design. Question : r/EngineeringStudents

Planetary gearbox Design. Question . I am working on a Planetary gearbox using 4 planet gears. It is for a traction reducers used on Continuous miners in the coal industry. However I have a difficult time as the planet gears doesn’t mesh well with the ring gear. (Imperial units) Ring Gear: Number of teeth: 56 Diametral pitch: 4 Pressure

New Planetary Gearbox: Design and Testing

The book introduces the design of planetary gear transmissions and provides in-depth coverage of a planetary gearbox with 2-DOF. It emphasizes the fundamental mechanical concepts and illustrates the theory with the worked out designs and prototypes. Also, the book presents key areas of kinematics, dynamics and testing of a planetary gearbox

+86-21-63353309

+86-21-63353309

Leave a Comment