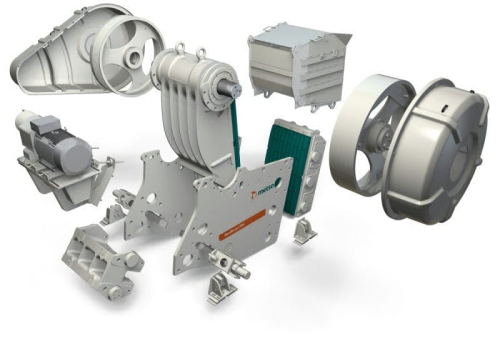

primary crusher example

Primary crusher

Engineering and architecture

The Effects of Accelerated Blast Timing on Primary Crusher

3/19 · Orica Quarry Services currently supplies a Rock on Ground (ROG) blasting service at Mawsons Lake Cooper Quarry, with the aim of this trial being to initiate a blast using accelerated timing and determine if measurable and significant production improvements could be delivered. On 29 April, , a 45,000 tonne trial blast was fired.

Choosing the right primary crusher for your aggregate

9/27 · The first step in choosing a primary crusher takes place at a high level. It’s necessary to identify the purpose the crusher will be used for. This purpose is a given that

Simplifying the crushing process - Pit & Quarry

Typically, the minimum setting on most primary crushers is about 4 in. to 6 in. Jaw, gyratory and impact crushers are most often appropriate as

Crushers - an overview | ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is

primary crusher - English definition, grammar, pronunciation, synonyms

Of the 160,000 tons of ore that go to the primary crusher each day, only 90,000 tons will end up as copper concentrate. jw (b) New crushers have to be segmented by technology (jaw crushers, cone crushers , primary gyratory crushers ) and by application (A & C and mining).

What is a Jaw Crusher? – MEKA Crushing Equipment

This is a type of crusher that is widely used in the primary and secondary crushing processes. It is usually preferred for the crushing of large blocks of hard

Type of crushers and their difference - JXSC Mining

12/10 · There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher consists of a fast spinning rotor and beaters attached to the rotor. The feed is entering to the crusher from the top and crushing starts

Crushers and Their Types – IspatGuru

4/3 · Types of crushers. Crushers are classified into three types based upon the stage of crushing they accomplish. These are (i) primary crusher, (ii) secondary crusher, and (iii) tertiary crusher. The primary crusher receives material directly from run of mine (ROM) after blasting and produces the first reduction in size.

TLC for Primary Crushers | E & MJ

Primary gyratory crushers are easily the hardest working piece of fixed plant on a mine site. The gateway between extraction and processing, they bear the brunt of continuous operation, high feed volumes, and are subject to rock particles of extreme size variation and hardness. It is therefore vital that they are kept in top condition

PDF TECHNICAL NOTES 5 CRUSHERS - Mineral TechPDF

Figure 5.1 Schematic diagram of a crusher showingg the open- and closed-side settings. 5.1 Jaw and Gyratory Crushers. Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is determined by its size.

+86-21-63353309

+86-21-63353309

Leave a Comment