rock crusher design

Design and Construction of Rock Crushing Machine from Locally

Design and Construction of Rock Crushing Machine from Locally Sourced 198 Materials for Indigenous Use. Aspects Min Miner Sci. 2(2). AMMS.000531.2018. DOI:

rock crusher - Recent models | 3D CAD Model Collection

The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third-party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray.

Rock Crusher History - Mineral Processing & Metallurgy

Many small process plants consisted of one crusher, either jaw or gyratory rock crushers, one elevator and one screen. Recrushing, if done, was taken care of by the same machine handling the primary break. The single crusher, when of the gyratory type, might be any size from the No. 2 (6″ opening) to the No. 6 with 12-in. opening.

How does a Rock Crusher Work - Jaw Crusher - 911 Metallurgist

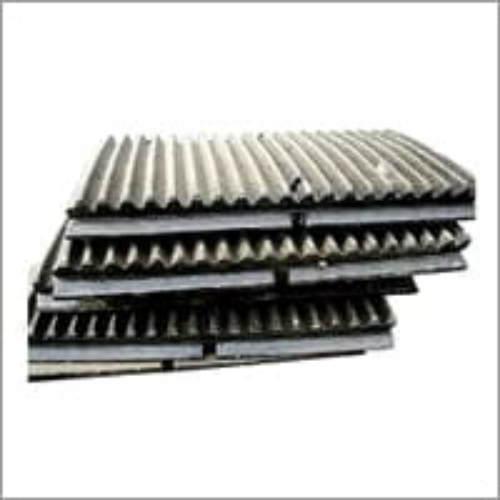

A jaw crusher frames are of sectionalized construction to facilitate handling. This design minimizes heavy lifts makes the crusher suitable

Rock Crusher - Scholar Commons

Senior Design Project Thesis Report - GRVLR. Generating Rock Volumes of Lower Radii (GRVLR) - Rock Crusher. Broyles, James Forman,

PDF Design of impact stone crusher machine - CitefactorPDF

crushers in use and have changed little from the original design. In Jaw Crusher the feed is compressed between a stationary and a movable surface. A few of common types of Jaw crushers, in use, are described below • Double toggle jaw crusher • Single toggle jaw crusher • Impact jaw crusher b. Gyratory (cone) crusher

PDF MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE - Mining and ...PDF

1. A typical example of primary crushing is reducing topsize from 900 to 300 mm. 2. A typical example of secondary crushing is reducing topsize from 300 to 100 mm. 3. a typical example of fine crushing is producing concrete aggregates in fractions below 30 mm. 4. Manufactured sand is typically smaller than 5 (often 2) mm. 5.

2022 New Design Hot Sale Distributors Crusher Items Jaw

2022 New Design Hot Sale Distributors Crusher Items Jaw Crusher Ppt Homemade Rock Crusher , Find Complete Details about 2022 New Design Hot Sale

Jaw Crusher Design Diagram Copper Rock Crusher Granite

Jaw Crusher Design Diagram Copper Rock Crusher Granite Gravel Phosphate Rock Pto Concrete Primary Jaw Stone Crusher , Find Complete Details about Jaw

Crushing Plant Design and Layout Considerations

primary crushing plant on solid rock reduces the cost of concrete and structural steel. Life of Mine/Expansion Plans The life of the mine is a key element in the design of any crushing

Rock Crusher Flywheel Design Criteria

Chapter 4 Design of flywheel for Jaw crusher 4.1 . Such a heavy crusher (16540x 2150mm) crushes rock, mineral or ore varying from 22.5 cm to.

+86-21-63353309

+86-21-63353309

Leave a Comment