spiral bevel gear vs hypoid

Hypoid Gears Selection Guide: Types, Features, Applications

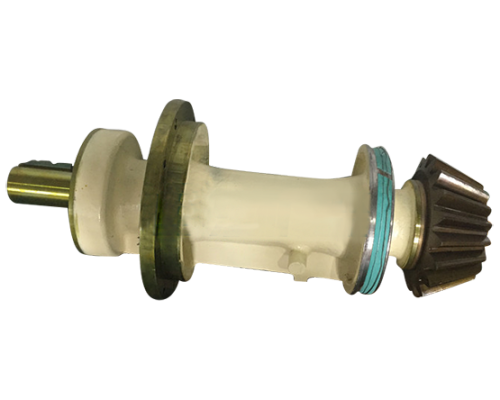

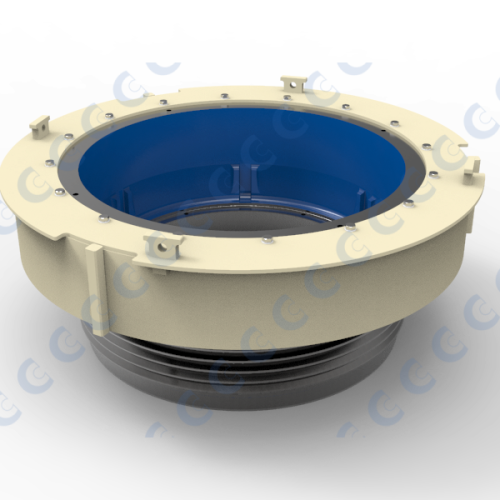

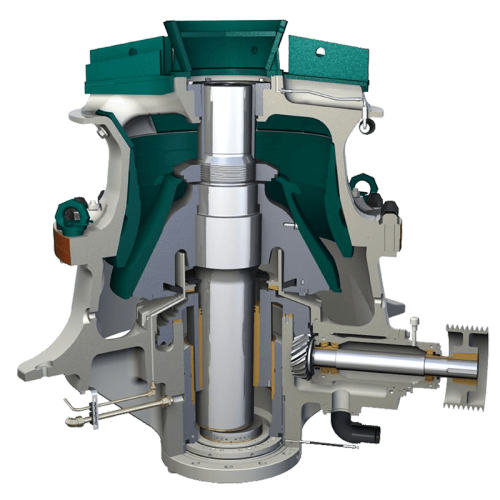

A hypoid gear is a style of spiral bevel gear whose main variance is that the mating gears' axes do not intersect. The hypoid gear is offset from the gear

Hypoid Gearing - Neugart

Hypoid bevel gears are among the spiral bevel gears. The advantage of hypoid gearing is that the bevel pinion can be realized with a greater spiral angle

Why Choose Spiral Bevel Gears?

Minimal Vibration – The shape of the spiral bevel gear teeth allow the gears to engage each other gradually and smoother than some of the

Hypoid vs Spiral/Bevel/Spur gears and their lubrication requirements

That is where the hypoid gear and "Torsen" differential were invented) Anyway, there is a fair amount of sliding between teeth of hypoid gears. The advantage of hypoid gears is twofold: They're stronger than right angle bevel gears, and quieter. I think there is a small amount of sliding in gears using an involute tooth mesh.

Less Energy Consumption with High-Efficiency Bevel gears

spiral bevel and hypoid gears in single-reduction axles. Introduction. The efficiency of a gearbox is the out- put energy divided by the input energy.

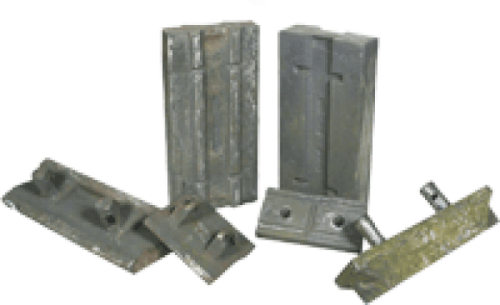

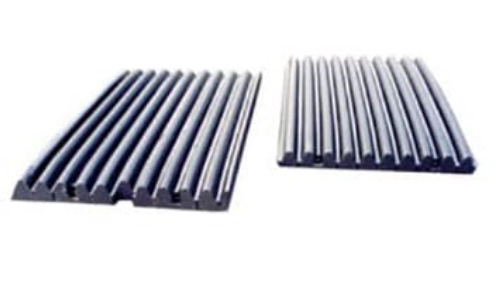

Spiral Bevel and Hypoid Gear Cutting Technology Update

introduced. Today, gears are made on high-production, automated machines with direct drives and precision cutting tools. Face Mill (Single Index) and Face Hob (Continuous Index). There

PDF Spiral Bevel and Hypoid Gear Cutting Technology UpdatePDF

There are two main meth- ods of producing spiral bevel and hypoid gears in the production environment today. There is the single indexing method referred to as face milling (Fig. 1), and the continuous indexing method (Fig. 2) referred to as face hobbing.

Hypoid VS Spiral Bevel Gear Systems

From a physical standpoint, there is just one main difference between the two different types of gears: In a spiral bevel gearset, the pinion center line

Spiral Bevel Gear - an overview | ScienceDirect Topics

Spiral bevel gears are smoother and quieter in operation than straight bevel gears, primarily due to a design that incorporates two or more contacting teeth.

high quality - helical-bevel-gear

Hypoid Bevel Vs Straight Spiral Bevel - What's the Big difference? Spiral gears arrive in a lot of diverse types, but there is a fundamental variation between a Hypoid bevel gear and a Straight spiral bevel. This article will explain the variations in

Spiral Bevel Gears and Hypoid Gears | SpringerLink

The load analysis of spiral bevel gears is then performed, also defining the thrust characteristic on shafts and bearings. Subsequently, the

+86-21-63353309

+86-21-63353309

Leave a Comment