working principle of gyratory crusher

Cone Crusher | Working Principle | Animation - Engineering Intro

Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from

working principle gyratory crusher - ataFinch

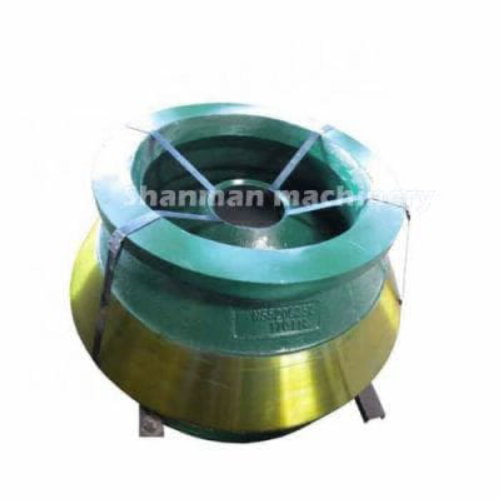

Working Principle of Gyratory Crusher. Gyratory crusher is mainly composedofdriving part, engine base, eccentric sleeve, crushing cone, middle bracket, beam, oil cylinder, hydraulic part, tackle, electrical part, dry and thin oil lubrication part.The space constituted by movable cone and fixed cone is crushing cone.

Gyratory Crusher : Principle, Construction, Working, and

A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardness. Gyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part, oil cylinder, pulley , appliances and dry oil, thin oil lubrication system components etc.

Working Working And Principle Of Gyratory Crusher In Tanzania

The working principle of the cone crusher - Term Paper . Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from crushing chamber. Cone crusher has a less steep crushing chamber and.

Industrial Solutions Gyratory crushers - ThyssenKrupp

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crush - ing chamber below.

Working Principle Of Gyratory Crusher Products

The Features And Differences Between Jaw Crusher And. In this article, we will introduce and compare jaw crushers and gyratory crushers. 1. jaw crusherorking principle. the crushing work of the jaw crusher is carried out by two crushing surfaces, which are crushed by the rapid collision of the intelligible tooth plates. the ore enters the crushing cavity from the upper feeding

wikipedia of gyratory crusher construction working

Contact Supplier operating principle of a gyratory crusher pdf. cone crusher Gyratory Crusher : Principle, Construction, Working, and A Gyratory Crusher

gyratory crusher working G10SEC V-BELT PULLEY SPC 530/8, ECCENTRIC

G10SEC TRMNL PLUG BUZ12-S 1756-a10 dimensions parts of stone crusher spare bush for a cone crusher mobile crusher parts. High-Speed Gyratory Crushing --> Fine Cone Crushers. Malaysia crusher machine,Gyratory cone crushers,Jaw crushers Gyratory crusher type KB 137-190 (54″-75″ installed in a semi-mobile crushing plant working in a copper ore

Explain The Working Principle Of Gyratory And Jaw Crusher

A jaw crusher crushes only a small proportion of the original aggregate particles but an impact crusher crushes mortar and aggregate particles alike and thus generates a higher amount of fine material (O'Mahony, 1990). Gyratory crushers work on the same principle as cone crushers (Figure 4.4(c)). These have a gyratory motion driven by an

Working Principle of Crushers - 911 Metallurgist

Gyratory crushers work on a similar principle to jaw crushers but have a circular gap. Rock is compressed between a static conical bowl and a concave mantle which oscillates about the central axis. These are generally designed for primary crushing in large-scale rock crushing applications up to 6000 t/h.

Gyratory Crusher Explained - saVRee

Gyratory crushers are always installed vertically orientated. A gyratory crusher’s size is classified by: Its gape and mantle diameter. The diameter of the receiving opening. Gyratory

+86-21-63353309

+86-21-63353309

Leave a Comment